The current average diesel price in the United States is $5.35 per gallon. Market analysts expect prices to stay above the current price until early 2023 when we could see a decline in price as per usual trends.

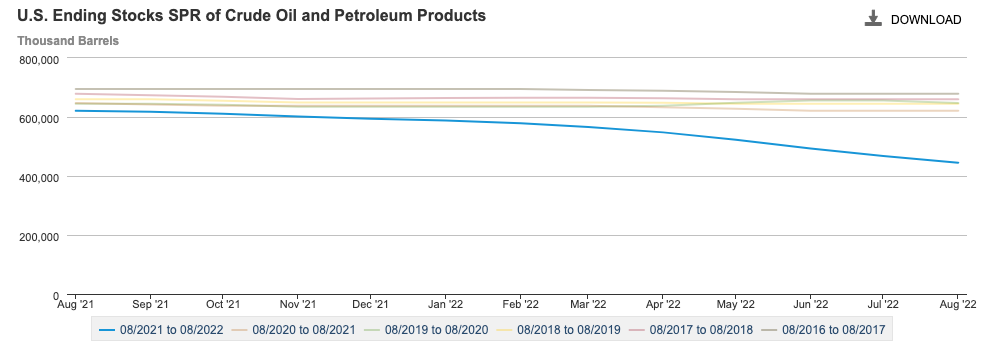

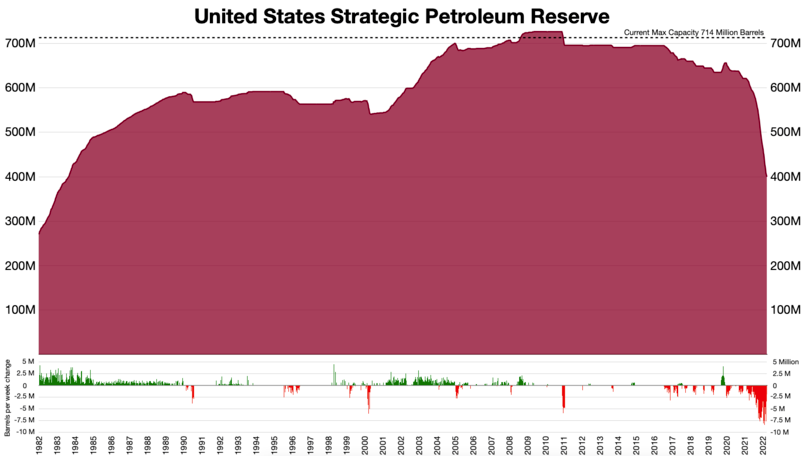

One factor playing a role in the price predictions is the Strategic Petroleum Reserve and changing policy around the size of the stockpile.

As shown in the graph above, 2022 marks the first year that the total stockpile has slipped below 600,000,000 barrels. Marking an important shift in the direction of the fuel markets and the constraints on the nation’s flexibility to come.

The rising costs of fuel have huge impacts on available cash flow to cover other expenses. To put it in perspective, the average long-haul truck will idle for 1,800 hours annually which consumes around 1,500 gallons of fuel every year. With a $0.50 increase in the price of diesel, the cost just to idle the average truck will increase by $750 annually.

Tips for Improving Fleet Fuel Efficiency

There are a few things companies might consider doing to reduce the burden of rising fuel costs. Some are more effective than others but when combined the savings add up.

#1 Top Line Speed Governors

When it comes to increasing engine efficiency, the number one thing that goes into the equation is usually driving behavior. Having a top-line speed governor installed in trucks will have an immediate effect on fuel consumption and savings. Although it might not make the drivers happy, the benefits for the company are worth the short-lived frustration displayed by drivers.

#2 Driver Training Programs

Most of the time drivers are already aware of the many ways to reduce fuel consumption while driving. Coasting down hills, following a maintenance schedule, reducing the total sum of time spent accelerating, etc. But these things are often scoffed at by drivers who see their primary focus as making sure they get their loads where they need to be on time and in a safe manner. Implementing quarterly training refreshers on the importance of effective driving habits is a great way to reinforce your company’s seriousness around the proper use of company resources.

#3 Simple Incentive Schemes for Drivers

Getting the right drivers in your trucks is a burden as it is. The driver shortage is only a small part of the issue. A greater factor is driver turnover, which currently sits above 90%!

Keeping drivers happy and employed with your company is a huge lever for improving profits and thriving during turbulent times. A few conversations per year with drivers about the things they want to see improvements around is a great way to identify the incentives that would motivate them to take energy use more seriously.

#4 Invest in Training Programs for Technicians

There are a few different ways that a power unit can experience reduced fuel efficiency. Including improper maintenance schedule keeping, improper cleaning of intake and exhaust systems, improper tire pressure, etc.

One way your company might consider improving overall awareness and efficiency across the board is by setting up short training programs on a regular basis that cover all the bases for improving performance. Not only can this increase power unit lifespan, but it also reinforces the company’s priority to optimize wherever possible. Especially while going into uncertain market conditions where it’s possible that many companies could have to lay off their staff.

More Ways to Increase Fuel Efficiency

- Minimizing cruise speed

- Manage Cruise RPM

- Buy fuel at the lowest-cost stations

- Optimize routes

- Plan ahead to avoid unnecessary miles

- Reduce total vehicle weight

- Monitor tire pressure

- Determine optimal idle times

- Reduce time spent braking

- Maximize cruising time in high gear

- Reduce drag by minimizing load height

- Maximize the use of momentum

- Inspect engine fan clutch (should run 5-7% of the time)

- Use cruise control and ensure the parameters for the speed ranges are reasonable (when the engine kicks on/off)