Overview

In recent years, the FMCSA has launched several initiatives to educate the public about commercial motor vehicle tires. Covering things like irregular tread wear, cracking, bulges, inadequate tread depth, cuts, foreign objects, interchangeability, and other damage. As well as things like tire pressures in different climates, dangers of exceeding speed ratings, and under/over inflation risks.

This article aims to cover the essentials that everyone involved in the transportation of highway freight should know. We will cover Manufacturers, Terms, Regulations, Tire Ratings, Inspections, Tire Positions, and Wear Patterns.

Leading Tire Manufacturers

- Goodyear

- Cooper Roadmaster

- Uniroyal

- Continental

Important Terms about tire wear

- Vulcanization: The process of heating rubber with sulfur to create pliable material.

- Rolling Resistance: The force required to keep a tire moving at a constant speed.

- Sidewall: The part of the tire between the tread and the wheel rim.

- Tread: The grooved material that makes up the outermost layer of a tire.

- Tread Depth: The measurement of the usable tread left on a tire.

- Traction: The amount of friction between the tire and the road surface.

Regulations

The first step is to be familiar with FMCSA regulations on commercial truck tires. The key rules are found in section 393.75. This section states that no motor vehicle should be operated on a tire that:

- Has ply or belt material exposed through the tread or sidewall

- Has any tread or sidewall separation

- Is flat or has an audible leak

- Has a cut to the extent that the ply or belt material is exposed

Any tire on the front wheels of a bus, truck, or truck tractor shall have a tread groove pattern depth of at least 4⁄32 of an inch when measured at any point on a major tread groove. The measurements shall not be made where tie bars, humps, or fillets are located.

(c) Except as provided in paragraph (b) of this section, tires shall have a tread groove pattern depth of at least 2⁄32 of an inch when measured in a major tread groove. The measurement shall not be made where tie bars, humps, or fillets are located.

(d) No bus shall be operated with regrooved, recapped, or retreaded tires on the front wheels.

(e) A regrooved tire with a load-carrying capacity equal to or greater than 2,232 kg (4,920 pounds) shall not be used on the front wheels of any truck or truck tractor.

(f) No motor vehicle may be operated with speed-restricted tires labeled with a maximum speed of 55 mph or less in accordance with S6.5(e) of FMVSS No. 119 at speeds that exceed the rated limit of the tire.

Read the full CFR by Clicking Here

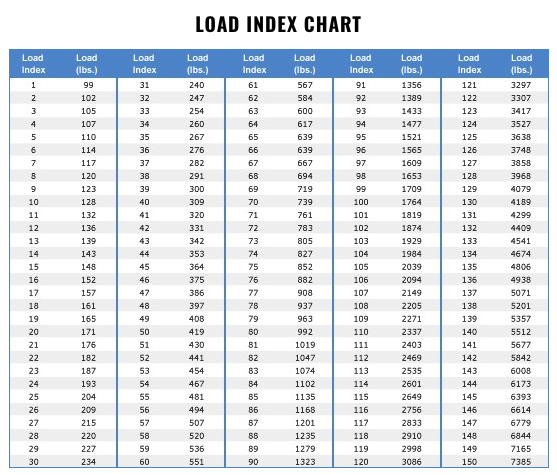

Tire Ratings

When you’re shopping for tires, you will notice a wide range of specs on the sidewall. These are there to describe the size, build type, limitations, axle placement, and road conditions they were designed for.

On the sidewall, you will find a string of letters and numbers like P235/75R15. Each character describes a different spec for that tire.

For Example 275/70R22.5 M 14PR

- Tire Size Ratio (275/70R22.5 M 14PR)

- 275 refers to the width of the tire in millimeters

- 70 refers to the sidewall relative to the previous number. In this case, it is 70% of the width or 192.5mm.

- Tire Internal Cord Construction (275/70R22.5 M 14PR)

- R = Radial

- B = Bias-Ply

- D = Diagonal Design

- Wheel Diameter (275/70R22.5 M 14PR)

- Is the size of the wheel fitment in inches

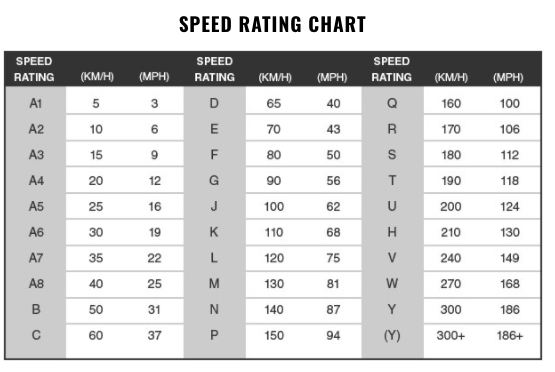

- Speed Rating (275/70R22.5 M 14PR)

- “M” indicates the tire has been approved for speeds up to 81 mph (Speed ratings range from A-Z).

- Ply Rating (275/70R22.5 M 14PR)

- Ply Rating = 14 Ply

Ensuring that your fleet is equipped with the right tires is essential. Not only will tire selection have an impact on the lifespan of the tires, but it will also have an effect on fuel efficiency, traction, ride comfort, and maintenance costs.

Tire & Rim Inspections

During inspections, drivers should ensure that tires do not have any of the following conditions before driving:

- Too Low/High Tire pressure (measured when cold)

- Irregular tread wear

- Cracking on the tire or wheel

- Bulges

- Inadequate tread depth

- Cuts and punctures

- Foreign objects

- Proper matching of tires/rims

- Missing or loose lug nuts

- Other damage

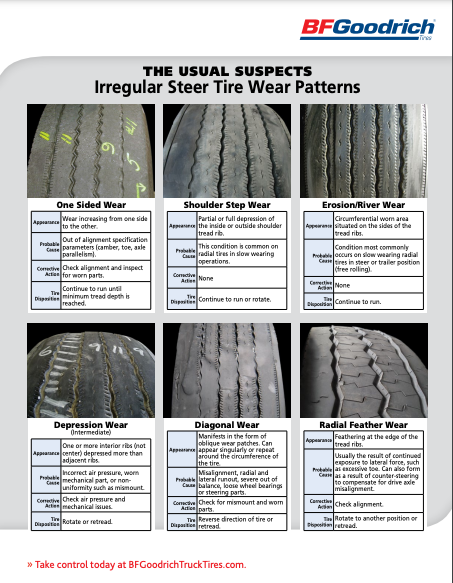

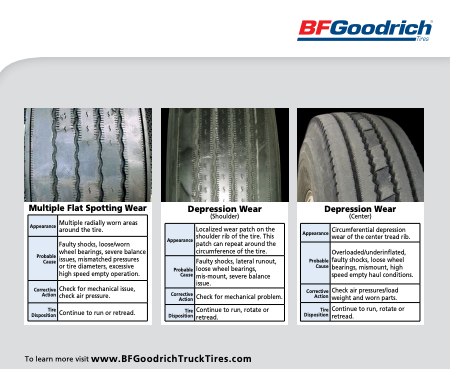

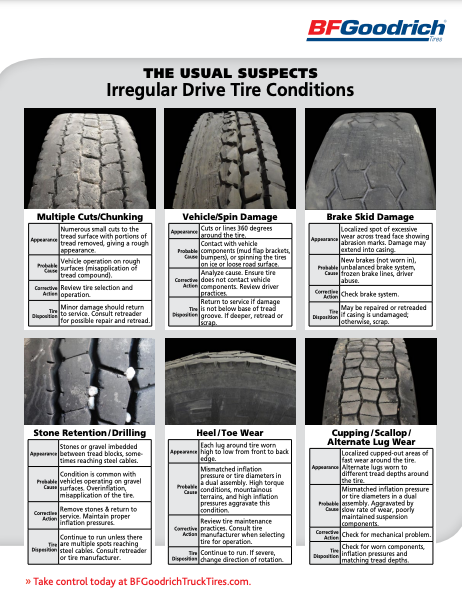

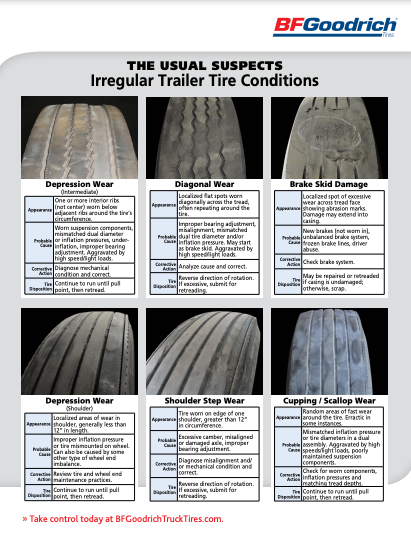

If any of these conditions are found to be present, the driver should seek a service shop immediately to either repair or replace the tires. A good rule of thumb is to keep a wear pattern diagram in the truck so drivers can detect irregular wear and/or suspension faults before they become an issue.

Tire Positions

Some tires are position-sensitive, while others can be placed on different axles. This is commonly done when tires are replaced at an offsite repair location to save money and avoid the markup from shops.

Steer Tires: NOT INTERCHANGEABLE.

Drive Tires: Can also be used for trailer tires.

Trailer Tires: Can be used for Drive Tires (although not recommended especially in winter driving conditions) for short distances so long as the size and weight rating are within the load parameters.

Tread Depth

Simply put, tire treads are what funnel water under/around the tire in wet road conditions. If a tire has no tread left, then the truck will suffer from little to no traction when the road is wet.

Steer Tires: According to Federal Motor Carrier Safety Administration (FMCSA) regulations, the minimum tread depth for a steer tire is 4/32 of an inch on every major tread groove. If one spot on one groove is less than 4/32, then a driver will be issued a citation. (Excluding the thin decoupling groove at the shoulder)

Drive/Trailer Tires: These same rules apply to drive and trailer tires, but the minimum tread depth is 2/32 of an inch in every major groove.

It should also be noted that tread depth readings can not be taken on a wear indicator or debris.

Wear Patterns

PDF Downloads: https://www.bfgoodrichtrucktires.com/tires/tires-101/tire-maintenance-and-safety/tire-wear/

Signs of a Bad Tire

Persistent air loss: Is a sign that the tire has been punctured, the valve stem is leaking, or the bead of the tire is not seated properly. Variants in temperature will also have an effect on tire pressure.

IMPORTANT: Steer tires should never be ‘plugged’ or ‘regrooved’.

Excessive vibration: If a vibration can be found coming from a tire, it’s usually a sign that the wheel is bent, unbalanced, misaligned, or internally damaged. It may also be caused when the tire/wheel is carrying too much debris. Drivers should NOT ignore tires that vibrate while driving. They MUST address this immediately to avoid an accident.

Cracking or Cuts: A tire with cracks or cuts in the sidewall has reached the end of its lifespan. Drivers should seek replacement immediately.

Uneven tread wear: Uneven tread wear can be a sign of several different issues ranging from incorrect tire pressure, suspension wear, improper hub seating, improper axle placement, and over-weighting axles. If the tires have not worn down to the wear indicators, sometimes tire rotations can be done to fix the issue and get the full lifespan out of them.

Excessively worn tread: Steer tires must have at least 4/32-inch while drive tires may wear down to 2/32-inch before they need to be replaced or the driver could face a violation.

Bulges or blisters: If a tire has a bulge or a blister on it, it must be replaced immediately. This is commonly seen when the sidewall of a tire is damaged. This kind of wear is irreparable and service should NOT be delayed.