With nearly 25% of roadside inspections leading to a vehicle being placed out of service, it goes without saying that a reliable vehicle maintenance program is essential for a safe fleet to stay on the road.

Here are some statistics and pointers to help you keep your fleet on the road:

- Check out the DOT-Ready.com software to streamline fleet maintenance record keeping and scheduling. It’s a small step that will save your company thousands.

- A clean fleet will keep the DOT off your back. Investing in a program for getting trucks and trailers washed will help keep your trucks out of the sights of the DOT.

- Preventative maintenance starts with drivers. Make sure they’re turning in their pre/post-trip inspections. The better communication between drivers and techs, the better maintained your fleet will be.

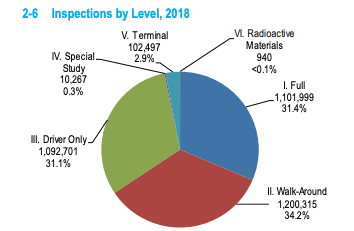

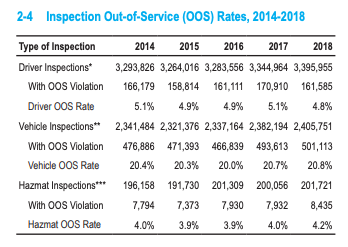

While we’re on the topic, here are some interesting statistics from the FMCSA regarding common violations and OOS rates from 2014 to 2018:

Here are some easily avoidable violations that drivers should easily be able to check for:

#1 – 396.3A1BOS – Brakes Out Of Service (99.9% OOS)

When the number of defective brakes is equal to or greater than 20% of the service brakes on the vehicle or combination, the unit is placed out of service 99.9% of the time.

#2 – 393.75A3 – Tire-flat and/or audible air leak (97.8% OOS)

When air can be heard leaking from a tire, or when a tire has a noticeable lack of air, the unit is placed out of service 97.8% of the time by the DOT.

#3 – 393.75F – Tire — exceeding weight rating of tire (98.25% OOS)

Tires are made to accommodate specific weight ratings depending on the type of vehicle it’s for and the road conditions it’s meant to be driven on. Be sure to check the weight ratings before purchasing tires so you don’t get put out of service down the road.

These violations lead to vehicles being placed out of service 98.25% of the time.

#4 – 393.43 – No/improper breakaway or emergency braking (90.3% OOS)

For vehicles equipped with an air braking system, this typically isn’t an issue due to the brakes applying themselves automatically whenever the air is drained from the tanks or the lines are disconnected. However, for electric brakes, it’s common for switches to become defective with age or connections to be so corroded that they don’t work when they’re supposed to.

These violations lead to vehicles being placed out of service 90.3% of the time.

#5 – 393.75A – Flat tire or fabric exposed (94.4% OOS)

Anytime a tire has exposed wiring or bulges, whether it be on the sidewall or driving surface, the tire must be replaced immediately. Drivers should be checking for issues with tires at least twice a day to avoid unexpected flats, or even worse, accidents.

These violations lead to vehicles being placed out of service 94.4% of the time.

#6 – 393.9BRKLAMP – Inoperative Brake Lamps (49.9% OOS)

Brake lamps should be checked every time the unit moves. Not only for proper operation but that the lights are bright enough to be visible in low visibility weather conditions that may be encountered.

These violations lead to vehicles being placed out of service 49.9% of the time.

#7 – 396.3A1BL – Brake system pressure loss (30.03%)

Air pressure should build from 85 to 100 psi within 45 seconds in a dual-air system.

With all brakes released, the air loss rate should be less than 2 psi in 1 minute for single vehicles and less than 3 psi in 1 minute for combination vehicles. With the brake pedal pressed, the air pressure can not fall more than 3 psi in 1 minute for single vehicles and more than 4 psi for combination vehicles.

These violations lead to vehicles being placed out of service 30% of the time.

#8 – 393.207F – Air suspension pressure loss (49.2% OOS)

The air pressure regulator valve shall not allow air into the suspension system until at least 55 psi is in the braking system. The vehicle shall be level (not tilting to the left or right). Air leakage shall not be greater than 3 psi in a 5-minute time period when the vehicle’s air pressure gauge shows normal operating pressure.

These violations lead to vehicles being placed out of service 49.2% of the time.

#9 – 393.45B2PC – Brake Hose or Tubing Chafing and/or Kinking (36.50%)

Air hoses must be secured against chaffing, kinking, or other mechanical damages; as well as be installed in a manner that prevents it from contacting the vehicle’s exhaust system or any other source of high temperatures.

These violations lead to vehicles being placed out of service 36.5% of the time.

How Trucking Companies Can Avoid Violations on the Road

There are several steps that trucking companies can take to avoid getting violations on the road. First and foremost, companies should make sure that their trucks are well-maintained and in good working order.

This means regularly inspecting and servicing the vehicles, and addressing any issues that arise.

Additionally, trucking companies should ensure that their drivers are properly trained and licensed and that they follow all applicable traffic laws and regulations. This may involve providing regular training and education for drivers, as well as monitoring their driving habits to ensure compliance.

Finally, trucking companies can use technology, such as GPS tracking and communication systems, to monitor and manage their fleet in real-time, and to quickly address any issues that may arise.