Following a routine maintenance schedule for regular wheel alignments can help reduce maintenance costs and improve vehicle safety. As well as helping to reduce expenditures towards things like fuel, downtime, and accidents. Regular wheel alignments on any vehicle, when properly maintained, can help to improve the vehicle’s handling, and fuel efficiency, and extend the life of the tires.

Improper suspension maintenance can lead to serious problems in the long run if companies aren’t staying on top of preventative maintenance services that include wheel alignments. Most trucks can go months without a proper suspension inspection, leading to unforeseen expenses and possible safety hazards.

One way to make sure things aren’t getting overlooked by technicians is to schedule regular wheel alignments. Even if it’s unlikely for components to be out of alignment, having a routine schedule for your mechanics could help identify problems long before they arrive. Oftentimes, simply asking mechanics to do visual inspections can identify problems ahead of time.

Rear Air Suspension

Rear suspension technology has come a long way since the old days. With most trucks having 4 airbags in the back, drivers might not even notice alignment issues that burn cash unnecessarily.

Two benefits of doing alignments:

- Alignments help ensure your tires wear evenly.

- Alignments help increase fuel mileage, helping you save money.

Common Issues Found During Alignments

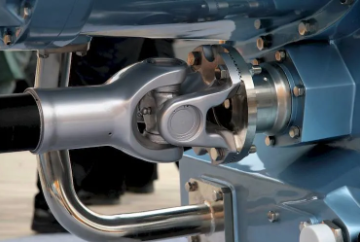

Truck repairs are a major cost for most companies. The best way to reduce those expenses is to replace parts before they cause wear and tear on other parts of the vehicle. U-Joints go out, steering shafts become loose, and misaligned tires cause unneeded tension on frame mounts.

Rear Axle Alignment

Even new trucks can require rear axle alignment. Some studies cite that up to 70% of new vehicles need some form of rear axle alignment. In one study of a fleet with 100 trucks, those with proper rear axle alignment operated at .79 cents per mile for tires compared to the misaligned of 1.8 cents per mile. Other fleets reduced tire operating costs from 1.9 cents to 1.2 cents.

Tire Resistance and Fuel Efficiency

According to other studies, around 80% of Class 8 tractors are operating misaligned, and over 90% of the trailers they pull have serious alignment problems.”

Fleets that prioritize correct rear axle alignment reported a gain of 3/10ths of a mile per gallon. For 100 trucks driving 125,000 miles per year, this translates into 1,100 gallons of fuel per year per truck.

As an example, a tandem tractor operating 125,000 miles yearly, with the front axle 1/4″ out-of-toe and the rear axles 1/4″ out of parallel would “scrub” the road 230 miles sideways.

Front axle wheel alignment can be broken down into three different measurements. By measuring the angle of tires, more stable driving conditions can be achieved and fewer maintenance issues will arise.

- Camber is the inward or outward angle of a tire when viewed from the front.

- Toe is the degree of the angle inward or outward when viewed from above.

- The caster is the angle of the tires when viewed from the sides.

Wheel Alignment Cost Breakdown

The cost of a wheel alignment at a 3rd party shop can vary depending on a number of factors, including the type of alignment needed, the location of the service, and the specific make and model of the truck.

In general, however, a wheel alignment usually includes Labor, Parts, additional services, and Taxes and fees.

As a fleet supervisor or safety manager, it is important to ensure that your mechanics are conducting regular suspension inspections on all of your vehicles. Suspension issues can lead to significant problems with the handling and safety of your vehicles, as well as increased wear and tear on tires and other components. To encourage your mechanics to prioritize suspension inspections, consider the following tips:

- Make it clear that suspension inspections are a priority: Make sure your mechanics understand the importance of regular suspension inspections and how they can help prevent problems down the road.

- Provide the necessary resources: Ensure that your mechanics have access to the tools and equipment needed to perform thorough suspension inspections, as well as any specialized training or certification that may be required.

- Set clear expectations and deadlines: Establish clear guidelines and deadlines for when suspension inspections should be conducted, and make sure your mechanics understand the importance of meeting these deadlines.

- Offer incentives: Consider offering incentives or rewards for mechanics who consistently conduct thorough and timely suspension inspections. This could be something as simple as a gift card or an extra day off.

By making it clear that suspension inspections are a priority and providing the necessary resources and support, you can encourage your mechanics to prioritize this critical maintenance task and save money.