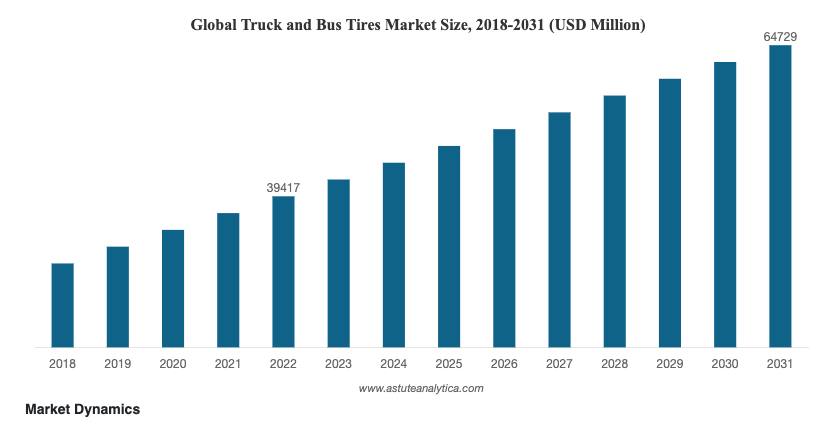

A core aspect of trucking company profitability comes down to tire prices and replacement intervals. The tire industry often gets overlooked as a factor to consider, but for large fleets, statistics can be an important benchmark for predicting operating cost.

This article will provide key insights into the current tire trends in the United States, highlighting the factors impacting prices and the ongoing production trends.

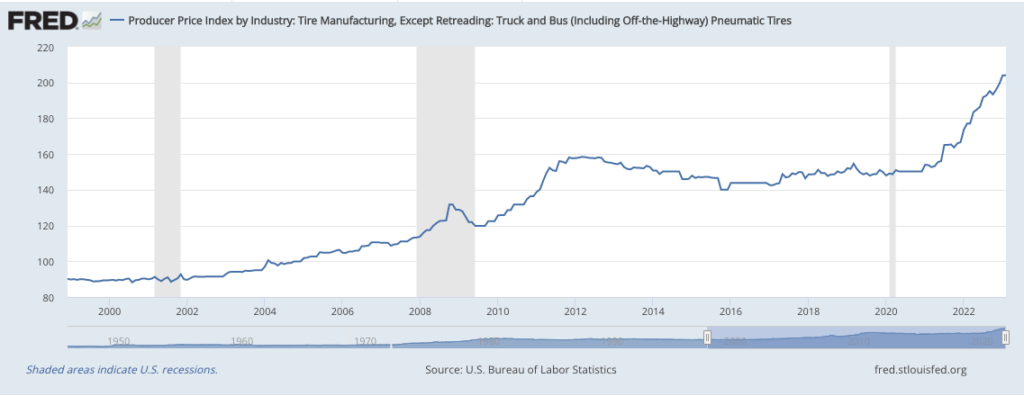

Tire Price Trends

In recent years, tire prices have been on the rise due to several factors, including increased raw material costs, rising labor costs, and fluctuating industry trends. The price of natural rubber and petroleum-based products has significantly increased, leading to higher production costs. Furthermore, the implementation of tariffs and trade restrictions has further exacerbated these price hikes.

Staying ahead of tire price trends can help fleets and owner operators reduce operational costs by enriching the dataset for purchasing decisions in the future.

Ongoing Production Information

A representative from Toyo Tires pointed out that heavy-duty and over-the-road truck tires are evolving to accommodate the needs of modern fleets. “New casing designs and nanocomposite polymers have resulted in more durable and stable tires with reduced rolling resistance, which is crucial for today’s mid to last-mile fleets. This keeps trucks on the road longer and enhances the fleet’s return on investment,” added the representative.

Noiseless Tire Market

The global market for noiseless tires is expected to grow significantly over the next few years. One primary reason for the growing interest can be attributed to public awareness of noise pollution and the desire to have a more peaceful ambiance in communities, in truck cabs, and for other pedestrians using the road.

The majority of consumers want tires to be as quiet and smooth-riding as possible, which explains the rising demand.

Fuel Efficient Tire Market

Some tire manufacturers are developing and improving product offerings to prioritize fuel efficiency. For example, Bridgestone has a line dubbed ECOPIA™ where fleets can use a calculator to see how much their fleet would save in fuel by purchasing their tires opposed to other leading tire manufacturers. There are a few tradeoffs fleets should consider before purchasing fuel efficient tires for the fuel savings alone. These include higher upfront costs, reduced tread life, reduced traction, limited availability, and compatibility issues. Although these factors are important to consider, some providers may still surpass the quality standards of regular tires while maintaining the savings benefit.

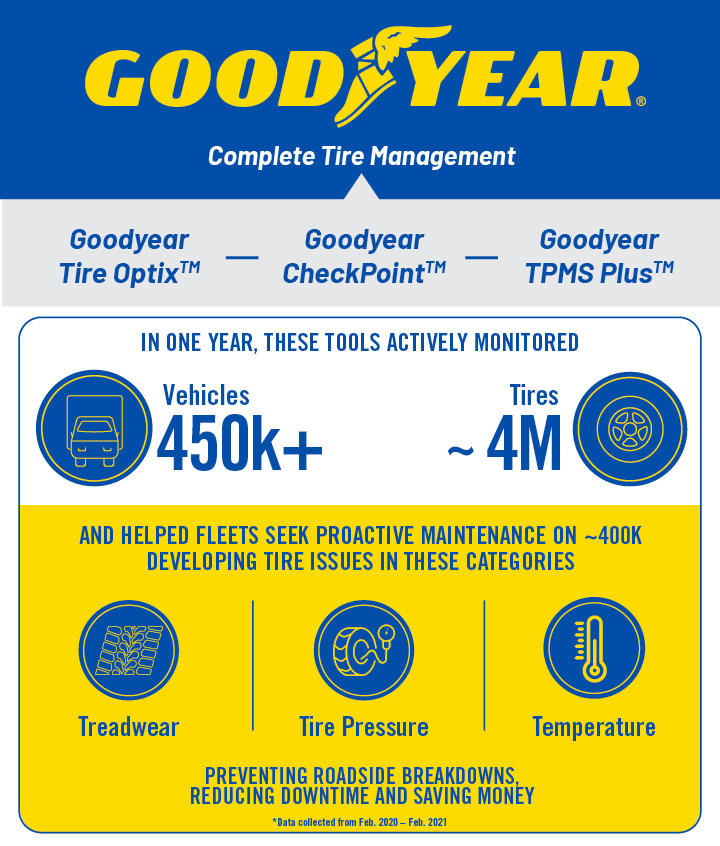

Modern Tire Technologies

Some tire manufacturers have developed modern tire monitoring technologies that assist fleets in identifying efficiency pitfalls and better maintaining fleet safety by bringing awareness to issues before they become serious. Some of these technologies include Goodyear Tire Optix™ which is a digital inspection toolset that helps fleets detect critical tire data. Other modern technologies include new molds, laser carving tools, and new test equipment to produce technically advanced tires.

Commercial Truck Tire Market Statistics

- The average price of a medium truck tire in the U.S. is around $400, while the average price of a heavy truck tire is around $600.

- Retreaded tires sell for 30-50% less than new tires and account for approximately 20% of the commercial tire market in the U.S.

- The U.S. government is one of the largest buyers of commercial tires, accounting for approximately 10% of the market.

- The average lifespan of commercial truck tires is 3-4 years.

- According to the National Highway Traffic Safety Administration, tire-related crashes in the U.S. account for approximately 738 fatalities and 19,000 injuries each year.